Cable ties are an invaluable asset for everything from bundling to securing packages. Yet, their versatility extends far beyond professional applications. With summer fast approaching, Cable Ties Plus would like to highlight eight warm weather projects made easy with the right cable tie!

- If you ever transport a bicycle on the back or hood of your car, use cable ties to secure the wheels so they aren’t constantly spinning. In fact, use cable ties to secure any items strapped to your car.

- If your gates don’t have locks, use cable ties when you want to make sure kids and pets don’t wander out, especially during a barbecue or children’s party. Your best bet here are detachable or reusable cable ties.

- In anticipation of your excursions on the water, use a cable tie to organize tubes, wakeboards, kneeboards, water skis, etc., especially when putting them away for the winter months. This way when you’re ready, everything’s in one place.

- Before you get going on mowing that lawn, lock the safety handle with a cable tie. Now you don’t have to hold the clutch the entire time!

- Having problems with wilting or leaning plants in the garden? Use lightweight, low tensile strength ties to stand them upright by attaching them to stronger plants, steel cages or other sturdy objects.

- If you’re agonizing over a broken metal ring on the basketball net, replace it with a cable tie.

- Take an ample supply of cable ties with you on your outdoor adventures. At the very least, use them to close off your pants at the ankles, ensuring nothing crawls up your leg. In the worst circumstances, they make excellent instruments should you need to apply a splint.

- Use cable ties to solidify your tent and avoid having it (embarrassingly) fall in on you as you brag about what a great outdoorsperson you are.

How about you? Do you have any unique uses for cable ties that would be helpful during the spring and summer? Share them with our readers and broaden everyone’s appreciation of these affordable and flexible products.

Clever Uses for Heat Shrink Tubing

Duct tape has a reputation for being able to fix anything and everything. However, did you know that heat shrink tubing is actually just as versatile? In fact, heatshrink is actually a more reliable solution, and in our opinion, much more elegant than haphazardly wrapping your broken items in unsightly gray tape.

Now, you might be asking – what exactly is heat shrink tubing?

Well, it’s a relatively thin-walled tubing often used to insulate complex wiring assemblies in everything from automobiles to aircraft, due in part to its ability to shrink rapidly with applied heat, sealing out debris, moisture, and harsh chemicals. Heatshrink is fabricated with many types of polymer bases, which affords the tubing exceptional mechanical strength and abrasion resistance.

All this to say, such a performance product is actually quite useful in everyday situations. Installation is simple. Pick the appropriate sized tubing (the largest size that will still shrink to a tight fix) and apply heat. Below are a few instances where shrink tubing is sure to save the day!

Broken Glasses?

Every glasses-wearer knows the misfortune of holding two separate pieces of your once marvelous spectacles in each hand. Don’t fret! With a little heat shrink tubing applied at the breaking point, you are back rockin’ your eyewear in style. Be sure to use a color that matches your frame color for a more streamlined fix.

Tangled headphone cables?

Twisted headphone cables are frustrating, and worse, all that stress on the cables can reduce their lifespan. The fix is simple with some heatshrink. Apply a few lines of tubing to your headphone cables in equal sections, so you can still fold them for transport. 3-inch sections of tubing will work great. And, while you’re at it, reinforce the jack with some heatshrink at the junction.

Too many keys?

We’ve all spent too long fumbling for just the right key in the dark. Or, maybe you’ve forgotten which key actually goes to the shed out back. A bit of heatshrink is a life-saver here. Apply different colors to the top plate of each key and identification is a breeze. Better yet, order some custom-printed heat shrink tubing, and you’ll always be sure where each key on the ring belongs. In addition to identification, heatshrink will prevent rusting on your keys and facilitate a better grip.

These are some simple and convenient uses for heat shrink tubing. While shrink tubing can seem foreign at first, once you get the hang of applying heat appropriately, you’ll be reaching for it whenever a quick-fix is needed. Installing heat shrink is always easier with the right tool, so we recommend you pick up a heat gun or torch, which offers the precision and control necessary for optimal application. If you have any questions about heat shrink tubing, call us here at Cable Ties Plus and we’ll be happy to assist.

More Unique Ways to Use Cable Ties!

Cable ties, also known as zip ties, have plenty of uses around the home, but have you ever thought of using them as part of your wardrobe? Use cable ties to make your own clothes or to enhance clothes you already have.

No-Tie Laces

Shoelaces are annoying. No matter how tight you tie them they always tend to become loose. You spend too much time bending over to tie them, especially on kid’s shoes. Velcro just isn’t visually appealing. That is, unless you’re using Velcro cable ties. They work just like regular cable ties. You pull the end through the opening at the tip and pull it tight. The end then wraps around itself thanks to the Velcro sides.

To use Velcro ties to make no-tie laces, you need to attach small rubber bands horizontally from hole to hole on the shoe. Attach the rubbers bands using the Velcro ties that you tighten into the lace holes. The rubber bands pull tight when you put your foot inside the shoe for a nice fit. The Velcro cable ties make removing rubber bands easy if you want to mix up colors.

Tie Dye Clothing

The trick to making fun designs on your tie dye clothing is to bunch up the clothing in different ways and keeping the bunch together with rubber bands. The dye doesn’t get inside the folds leaving white areas once dry. Unfortunately, rubber bands can sometimes snap during the dying process, and the dye often seeps in below the rubber band, ruining the design.

Eliminate these problems by using cable ties. You can use any type of cable tie, but the most effective will be releasable cable ties. They have little tabs that you press to unlock, so you don’t have to get out the heavy duty scissors. The ties work just like the rubber bands, except they won’t break and the tightness of the tie guarantees that no color will seep through into unwanted areas. Also, cable ties come in many different lengths so you can make different designs.

DIY Corset

Corsets are classic accessories that are often expensive to purchase and too difficult to make. They require special boning that creates the shape of the corset. It’s what keeps it taut while pressing into your body. While creating that strength, it also bends enough so you can move around without difficulty. Boning can be expensive, and if you mess up during the process, then you’ll have to buy more materials.

Cable ties are much cheaper and work just like boning. Standard cable ties can withstand up to 50 lbs of pressure. No matter how tight you wear your corset, the tie will hold up. If something goes awry, you’ll have plenty more cable ties to work with without emptying your wallet.

We always love hearing about unique ways to use our products. Contact us with your ideas!

Fixing an Ethernet Cable with Zip Ties!

We’ve all been there. You just finished that important email, only to find you’ve lost Internet. After a computer restart and a ‘friendly’ smack on the side of your router box, you realize the culprit. That old Ethernet cable has fallen out from its slot, all because the pesky little plastic clip has broken off! Before you make a mad dash to the store to pick up an overprice replacement cable, head to the toolbox and grab some cable ties. With just two ties you can get your Internet up and running again in no time.

For this quick fix, you’ll want to start with the smallest zip ties you have. Miniature ties work best, but you can use any length you like as you’ll be trimming them down regardless. Step one is to trim down (and file for added precision) the head of one tie to match the thickness of the original cable clip end (so it ultimately fits in the slot on your computer). Use a suitable utility knife for trimming and a metal nail file for filing. Next, you’ll want to shorten the tie whose head you just filed. Cut the tape portion of the tie to around 2 inches. Scissors will work just fine.

* We can’t stress this enough, but please exercise caution when using sharp tools to modify cable ties!

Next comes a bit of a song and dance, as we will be combining the ties to replicate the clipping mechanism. Take the unmodified cable tie and wrap it around the cable, just behind the cable’s plastic end. Before you tighten, loop the shortened cable tie under the tie you just wrapped around the cable, making sure you insert the tail pointing toward the end of the Ethernet cable (where the broken plastic clip is). Now tighten the tie holding our trimmed tie in place. If you’ve done this correctly, you should be able to push down the modified head so that it rests on the plastic end of the cable where the clip originally broke off. It’s usually a good idea to cut off any excessive tape length on our unmodified tie, which is holding the “zip tie clip” in place.

Now, while continuing to push down the filed (or trimmed) cable tie head, slide the cable into the appropriate slot on your computer or router, and there you have it! An Ethernet cable that fits snugly and won’t slide out during use. Now of course, this isn’t a permanent fix, and you’ll have to reapply pressure on the apparatus to reinsert the cable. But, with just a few zip ties from Cable Ties Plus, you can be ready for an unfortunate cable failure, helping you get online and back to work.

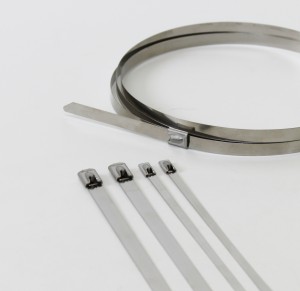

Stainless steel cable ties are the perfect solution for secure bundling where you need to consider specific environmental conditions. They have a temperature range between –112°F (-80°C) and 1000°F (538°C) and tensile strength starting at 100 pounds. That puts this product in a category all by itself with practical uses in many projects and industries.

Cable, or (‘zip’) ties are simply the best way to securely safeguard systems. But not all cable ties are created equal. There are unique circumstances that may require features not found in every cable tie product. For instance, weight is a significant factor in determining what type of cable tie should be applied. An outdoor project might require ties with characteristics that are unnecessary indoors. There may be risks to consider, such as an environment where exposure to chemicals must be taken into account or where an installer has to account for potential accidents or even theft.

Stainless steel cable ties are engineered with all the design of conventional ties but made from one of the strongest materials in the world. This makes it ideal for situations that require a higher level of resistance, strength, and durability.

Stainless steel cable ties are not susceptible to corrosion, staining, or rusting. They can be applied in situations where moisture is a concern. This makes them perfect for cables, wires, and assemblies that might be exposed to water, extreme temperatures, or set in dirt. It’s why many professionals turn to stainless steel ties for projects involving food processing, agriculture, and plumbing.

Situations involving heavy equipment are also ideal for stainless steel cable ties. In environments where anything from paper mill equipment to heavy construction tools need to stay in place, a stainless steel cable tie can do the job, either permanently or temporarily depending on project needs. Their strength maximizes security throughout operations, minimizing the possibility of tools or equipment shifting or moving when you least need them to.

If exposure to chemicals, deteriorating gases, or other hazards is a concern, stainless steel cable ties are the way to go. From hospitals to laboratories, this easy-to-install product offers a level of protection that both stands up to exposure and meets high standards regulated by governing bodies that inspect or audit the premises.

With this zip tie’s potential to stabilize hundreds of pounds and resist corrosion, as well as its cost effectiveness and ease of use, you will want to keep a nice stock of stainless steel cable ties around. Offered in a series of sizes and strengths, get these ties with a self-locking mechanism that simplifies coordinating your systems even more. And get them from CableTiesPlus, the leader in products you need to operate efficiently and effectively.

Cable Ties Plus has always promoted cable ties for their simplicity and utility. They are an indispensable asset for aircraft mechanics, cable installers, plumbers, fishermen, the military and more. We cannot stress enough that even the novice DIY-er should keep these tools in their workshop.

Believe it or not, after lauding over the cable tie’s ease-of-use, we’re going to reveal how to make using them easier than ever. We’re talking about the cable tie installation tool. Cable tie installation tools save time, money and, in the long term, minimize the types of health risks associated with repetitive movement.

Outside of lower back pain, tissue injuries due to repetitive hand motion are one of the most common ailments in the world. Even the most innocuous everyday motions can lead to disorders such as bursitis and tendinitis. Repeatedly twisting ties – among the many other tedious hand movements associated with electrical work – definitely falls into this category.

With a cable tie installation tool, you can start assembling even the most intricate systems with less stress on the hands and with greater ease. Lightweight and reliable, another advantage of this resource is you can place a cable tie with minimal fuss. Suddenly you’re not worrying about those hard to reach areas, which require extensive reaching, stretching and uncomfortable contortion of limbs. The device has a convenient pistol grip, meaning you’ll be able to apply cable ties with a single hand. Pull the trigger and not only will the cable tie cinch, but a simple twist of the tool removes any excess strap. All done.

Of course, like any tool, getting the job done requires having the right tool variant. Cable ties are engineered from nylon, metal and plastic. Each is designed to handle unique situations. The same applies to cable tie installation tools. One tool might be perfect for jobs that have a maximum capacity of 50 pounds. Another handy cable tie installation tool may be best suited for heavy duty projects, such as stabilizing machinery or securing cable ties that hold hundreds of pounds. You may prefer features like adjustable tensioning or a tool that can cut metal ties, as opposed to one that can only handle lighter materials.

We believe the cable tie installation tool will significantly improve your workflow. Cable Ties Plus knows quality cable accessories and understands the different demands for various industries, professionals and projects. We are all about effectiveness, quality, productivity and affordability. Call us today and ask about our cable tie installation tools!

Using Cable Ties for Transport

Whether the job is flatbed transport on the back of a pickup truck, or a full-size semi trailer load, the most important element of the entire operation, by far, is safely securing the load before the transportation process even begins.

For sale, legal transportation of goods on the truck flatbed, there can be absolutely no ‘loose’ piece of goods; goods not secured by safe, approved means. CableTiesPlus offers a wide variety of zip cable ties that can be a safe, secure option, suitable for many transport needs.

Cable ties are used to secure items together and are easy to apply, economical, and provide the safety and assurance in securing the load that the driver needs to rely on. For intermodal truck operations, cargo crates must be properly secured to the chassis. The chassis pin can be easily locked with a zip tie, and many transportation organizations actually require this reinforcement. Use a bright-colored tie, such as yellow, as they will be easier to identify during inspections and you can be on your way.

Cable ties are also quite useful on a truck-bed when you need a reliable solution for quickly fastening-down items, and we recommend heavy-duty or extra-heavy-duty ties with tensile strengths of 120 lbs. and 175-200 lbs., respectively. Whether it’s a ladder or a spare tire, a few zip ties will secure the item for the trip. You can also use extra-heavy-duty tie to attach straps to your truck-bed, holding down your items with confidence in a pinch.

For heftier applications, such as large crates and boxes, cable tie strapping is available in roll kits of 100′ and 200′ 6/6 nylon strapping. This strapping is thinner, easier to install, and is more flexible than heavy-duty cable ties, and can be cut to custom lengths. With 400 lb. of tensile strength, kits come complete with 25 cable tie heads. According to length preference, custom-length rolls are also available to order. With strapping, you can be assured your items are properly secured for transport.

For all these products, and a great deal more to assist in any equipment need for cable ties and related accessories, CableTiesPlus has an extensive line of products that will help keep loads of any size safe, secure, and ready to hit the road.

Choosing the Right Cable Tie

The use of cable ties is common in many industrial, mechanical and electrical applications. You may have heard these called by a different moniker, such as wire wraps, Ty wraps, nylon ties or cable wraps. All are the same and refer to the same device. The question being asked here is what strength or length of cable tie should be used.

Materials

Cable ties may be manufactured from a variety of materials, such as:

- Nylon

- Stainless steel (non-detectable)

- Detectable metal

- Fluoropolymer

Additionally, there are cable ties that are weather resistant, heat resistant and oil resistant. Some are releasable and reusable; some are not. Some use Velcro while others use a pull through design closure. Some are even impact resistant. Many come in a variety of colors that aids in quick identification.

Sizes/Strengths

If you have ever purchased cable ties, you know that they are available in many lengths and widths. This, however, does not necessarily correspond to strength rating. All of these ties are rated by a loop tensile strength or LTS, which is stated in pounds. The most common ties range between 18 lb and 175 lb.

The LTS is the maximum amount of force that can be exerted on the locking mechanism once it has been deployed.

Maximum Diameter

This refers to the largest diameter of the bundle to be tied or restrained.

Length & Width

The cable tie should fit around the bundle and the loose end pulled completely through the locking device. As long as the tie fits the bundle and can be locked securely, it’s all good. Longer ties can be used to secure items, such as cargo or merchandise.

Temperature Range

Consider the operating conditions inherent to the intended application. Will the tie be utilized inside or outside? Will there be any extreme cold or heat that will affect the cable tie? Keep in mind that cold temperatures can cause most nonmetallic materials to brittle.

So how exactly do I decide what cable tie to use?

Now that you know a little about the specifications on the cable wraps, you should have a good idea how to pick the proper one. As far as size, that is a matter of your judgment. Measure the diameter of the bundle to be tied and then select the cable tie that best fits the need. Consider the environment in which the tie will be utilized. If there will be excessive heat involved, possibly use a metal cable tie. If extreme cold is expected, use a tie that is either temperature or cold resistant. Assess the presence of oils, liquids or fluids to determine if you need to select an oil resistant cable tie.

Here at CableTiesPlus, we are always ready to assist you in finding the perfect cable tie for the job. Give us a call!

Unclog Your Sink With Cable Ties

We’ve all been there, quietly washing our hands as the soap foams under the warm water. Thanks to Covid, you’re probably singing ‘happy birthday’ to yourself to get those 30 seconds in, or eyeing yourself in the mirror, when you look down and notice the murky water beginning to pool in your sink. The dread sinks in as you realize the unavoidable – your sink is clogged. You can either get used to stale water festering in the sink for weeks, or shell out money for a plumber. Drain cleaner perhaps? Unfortunately, these cleaners are often ineffective, and worse, can cause damage to your plumbing system. If you’re renting, your landlord might not even allow drain cleaners, especially if the house is older.

This is where the simple and versatile cable tie comes into play. Also known as the “tie wrap” or “zip tie”, these unassuming tools will be a lifesaver in our ‘clogged-sink’ predicament. Head to the toolbox and grab a cable tie (the longer the length the better), as well as a wire cutter. The solution is straightforward. Using the cutters, clip diagonal notches the entire length of the cable tie on both sides, alternating your slots for best effect. Next, gently bend each notch outward to create bards, which will grab onto to gunk accumulated in your sink pipes.

Now comes the fun part. Take your barbed tie and force it as far down as possible into the drain, pulling carefully to extract the clog culprits, be it grease, hair (most likely lots of it), or any other sorts of drain congestion. Repeat until water drains freely down the sink and there you have it – a quick and easy plumbing fix, utilizing tools you probably have around the house, saving time, money, and even possible damage to your plumbing system.

As you can see, cable ties have an almost endless number of applications, some traditional, such as securing cable bundles, but others more inventive – like our clogged sink! Be sure to keep cable ties in your toolkit, and contact us if you have questions about our ties. Also, let us know of the clever ways you use this remarkable tool!